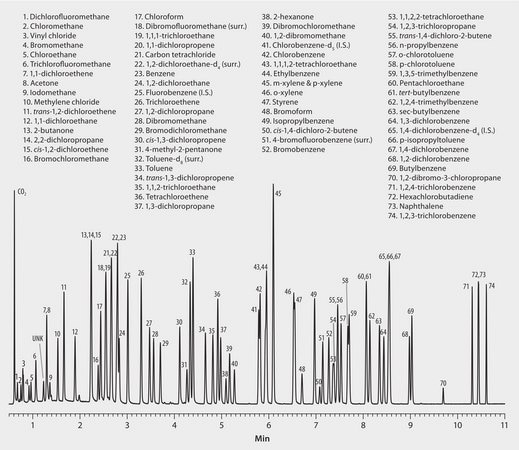

US EPA Method 8260: GC Analysis of Volatiles on SPB®-624 after Purge & Trap using "K" Trap, Fast GC Analysis

Materials

analytical column

accessory

Hamilton® syringe, 1000 series GASTIGHT®, PTFE luer lock

1005TLL, PTFE Luer lock, volume 5 mL, needle size (not included)Hamilton® syringe, 1000 series GASTIGHT®, PTFE luer lock

1005SLPT (for Purge & Trap), volume 5 mL, needle size (not included)related product

EPA Vials, white polypropylene screw top hole cap, pre-cleaned and assembled

volume 40 mL, amber glass vial, O.D. × H 29 mm × 82 mm, pkg of 72 easample prep

Purge/Trap K Vocarb® 3000

for use with Tekmar® Velocity XPT, LSC-1, LSC-2, LSC-2000, 4000 (Straight, 12 in./30.5 cm, Swagelok fitting), HT-3Purge/Trap K Vocarb® 3000

for use with Tekmar® 3000, 3100 (Straight, 12 in./30.5 cm, Valco fittingstandard

EPA 8260A Surrogate Standards Mix

certified reference material, 2000 μg/mL each component in methanolEPA 8240B/8260A Matrix Spike Mix

certified reference material, 2500 μg/mL each component in methanolEPA 8260 Volatiles Calibration Mix

certified reference material, 2000 μg/mL each component in methanolCONDITIONS

sample/matrix

each analyte at 50 ppb in 5 mL water

purge trap

VOCARB 3000 K (24940-U)

purge

40 mL/min at 25 °C for 11 min

dry purge

2 min

desorption preheat

205 °C

desorption temp.

210 ºC for 1 min

desorption flow

150 mL/min

bake

260 °C for 10 min

transfer line/valve temp.

110 °C

column

SPB-624, 20 m x 0.18 mm I.D., 1.0 μm (28662-U)

oven

40 °C (1 min), 11 °C/min to 125 °C, 35 °C/min to 230 °C (2 min)

inj. temp.

150 °C

MSD interface

220 °C

scan range

m/z = 35-400

carrier gas

helium, 1.5 mL/min

injection

100:1 split

liner

0.75 mm I.D. SPME

Description

Analysis Note

US EPA Method 8260 describes the analysis of volatile organic compounds in solid wastes and ground waters. This application illustrates the analysis of many compounds commonly analyzed by this method using purge and trap coupled to GC-MS. A short, narrow I.D. SPB-624 column was used to shorten the analysis time to under 11 minutes. A high desorb flow through the trap was necessary to prevent band broadening of the gaseous VOCs. This was accomplished by increasing the split ratio, thus increasing the total flow through the trap during desorb.

Legal Information

SPB is a registered trademark of Merck KGaA, Darmstadt, Germany