Performance of Whatman™ 40 and 41 Quantitative Ashless Filter Paper Grades in Mining Quality Control Applications

The aim of this work was to demonstrate the performance of Whatman™ Grade 40 and Grade 41 quantitative ashless filter paper in specific mining industry applications. Whatman™ Grade 40 and Grade 41 filter paper was evaluated in three metal content tests typically used in quality control laboratories—high molybdenum, lead, and zinc analyses. Whatman™ Grade 40 and Grade 41 quantitative ashless filter paper met the customer’s requirements for filtration speed, clarity, and metal content in all tests. These requirements were achieved because these quantitative filter papers are manufactured to strict specifications that are important to mining industries. The data presented here show the suitability of Whatman™ Grade 40 and Grade 41 filter paper for these three analyses.

Introduction

In mining industries, analytical quality control (QC) laboratories routinely test the content of different metals in ore samples. Sample preparation is a critical factor in obtaining consistent results. Therefore, the use of high-quality, dedicated filter paper is expected to improve the accuracy of these metal content tests. Whatman™ quantitative filter paper from Cytiva is made from pure cotton and treated to wash away most of the impurities. Whatman™ quantitative paper is useful for gravimetric analysis and the preparation of samples for instrumental analysis. Compared with other papers, Whatman™ quantitative ashless filter paper (Figure 1) gives high loading capacity and particle retention, both of which are useful for the analysis of metals and other substances in ore samples.

Figure 1.Whatman™ Grades 40 and 41 quantitative ashless filter paper

Materials and Methods

High Molybdenum Analysis

The performance of quantitative filter paper is important in high molybdenum (Hi Mo) testing. The major critical to quality (CTQ) factors in performance testing are filtration speed, clarity of filtrate, and molybdenum (Mo) content. Analyses were performed on ten samples using Whatman™ Grade 40 paper and the following procedure.

Procedure for Hi Mo Testing

- A 0.20 g (± 0.1 mg) sample was weighed into a 250 mL beaker, then 30 mL saturated solution of nitric acidpotassium chlorate and 20 mL hydrochloric acid were added to dissolve the sample.

- Hot water and 40 mL ammonia were added to precipitate the interference metals, which were then removed with a qualitative filter paper.

- A methyl orange indicator solution (4 drops) was added to the filtrate. A 1:1 ratio of hydrochloric acid and water was used to adjust the filtrate to pink to facilitate lead molybdate precipitation, then 50% ammonium acetate was used to adjust the filtrate back to orange.

- A 4% lead acetate/40% glacial acetic acid solution (30 mL) was slowly added to the beaker with stirring to precipitate the lead molybdate.

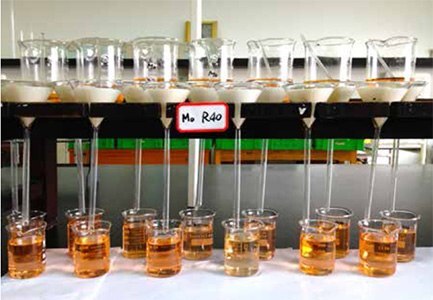

- The precipitate was separated from the solution with two layers of Whatman™ Grade 40 quantitative filter paper (Figure 2), then the precipitate was washed 10–12 times with hot ammonium nitrate/2% ammonia.

Figure 2.Retention of lead molybdate precipitate using Whatman™ Grade 40 filter paper.

- The filter paper with precipitate was placed in a muffler oven at 600 °C for 20 min to obtain a constant weight.

- The percent of molybdenum was calculated using the following formula:

Lead Analysis

The performance of quantitative filter paper is important in lead analysis, which is one of the major applications in mining industries. The major critical to quality (CTQ) factors in performance testing are filtration speed, clarity, and lead (Pb) content. Analyses were performed on ten samples using Whatman™ Grade 40 quantitative filter paper and the following procedure. The results were compared with the benchmark requirements.

Procedure for Lead Analysis

- A 0.10 g (± 0.1 mg) sample was weighed into a 250 mL beaker, 15 mL concentrated hydrochloric acid was added, and the beaker contents were allowed to boil for a few min. Nitric acid (5 mL) was added, and heating was continued until the sample was nearly dry. Then 10 mL concentrated sulfuric acid was added, and the beaker was heated until heavy white smoke was visible. The solution was then cooled to room temperature.

- Water (60 mL) and tartaric acid (2 g) were added, and the beaker contents were allowed to boil for 3 min. The outside of the beaker was cooled with water for 40 min, until a precipitate (PbSO4) formed.

- The precipitate was separated from the solution with one layer of Whatman™ Grade 40 quantitative filter paper (Figure 3), then the precipitate was washed with 2% sulfuric acid until no iron could be detected.

- The filter with precipitate was placed back into the 250 mL beaker, 40 mL sodium acetate/glacial acetic acid buffer solution was added, and the beaker contents were allowed to boil for 3 min.

- Water (60 mL), ammonium citrate (10 mL), and 0.2% xylenol orange reagent (2 drops) were added. Titration was performed with a 0.011 M EDTA solution.

- The lead concentration was calculated using the following formula:

Procedure for Zinc Analysis

- A 0.20 g (± 0.1 mg) sample was weighed into a 400 mL beaker, a small amount of water and 15 mL hydrochloric acid were added, and the sample was heated to boiling for approximately 3 min to dissolve and remove hydrogen sulfide.

- Nitric acid (5 mL) was added to completely break down the sample. Sulfuric acid((12 mL, 1:1 in water))was added, and heating was continued until white smoke was visible. The sample was cooled to room temperature.

- Ammonium chloride (40 mL, 20%) and 5 mL highly concentrated ammonium hydroxide were added to the sample solution, which was then heated to boiling and boiled for 3–5 min. The precipitate was removed using Whatman™ Grade 41 quantitative filter paper (Figure 4). Warm cleaning solution (concentrated ammonium chloride and ammonium hydroxide) was used to wash the beaker and the precipitate 2–3 times each to a total volume of about 300 mL. The filtrate was evaporated to a volume of about 200 mL and was used in step 4.

- To the filtrate 5 mL potassium chloride (20%) and 2 drops ascorbic acid were added, followed by 1 drop of methyl orange indicator (0.2%). Sulfuric acid (1:1 in water) was added until the solution just turned red. A saturated solution of sulfourea (5 mL) was added, then 20 mL acetic acid-sodium acetate buffer was added. An EDTA standard solution was used to titrate the solution to a bright yellow color.

- The zinc concentration was calculated using the following formula:

Results and Discussion

High Molybdenum and Lead Analyses

The results for ten samples of Whatman™ Grade 40 quantitative ashless filter paper used in high molybdenum and lead analyses are presented in Tables 1 and 2, respectively. A consistent filtration speed and performance was obtained in both analyses. The customer is satisfied with the performance of Whatman™ Grade 40 filter paper in high molybdenum and lead analyses.

Zinc Analysis

The results for ten samples of Whatman™ Grade 41 quantitative ashless filter paper used in zinc analysis are provided in Table 3. Consistent filtration speed and performance were achieved. The customer is satisfied with the performance of Grade 41 Whatman™ filter paper in zinc analysis.

* Filtration speed varies according to the funnel size, sample volume, and experimental conditions

Conclusion

This work demonstrates that Grades 40 and 41 of Whatman™ quantitative filter paper show good separation performance, speed, and repeatability in high molybdenum, lead, and zinc analyses. All of the customer requirements were met for all three tests. Therefore, these papers have the potential to improve the quality control process in mining industries.

Acknowledgement

Data for high molybdenum, lead, and zinc analysis were kindly provided by Hubei Geological Research Laboratory, Hubei, China.

To continue reading please sign in or create an account.

Don't Have An Account?