About This Item

Recommended Products

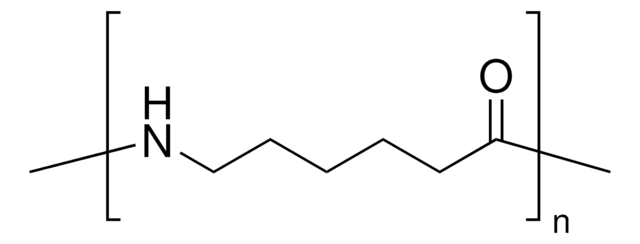

form

pellets

Quality Level

autoignition temp.

815 °F

transition temp

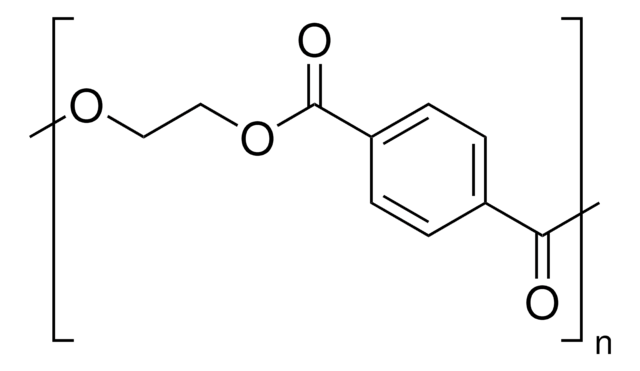

Tm 228.5 °C

Tg 62.5 °C

density

1.084 g/mL at 25 °C (lit.)

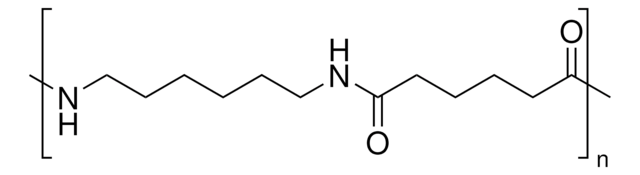

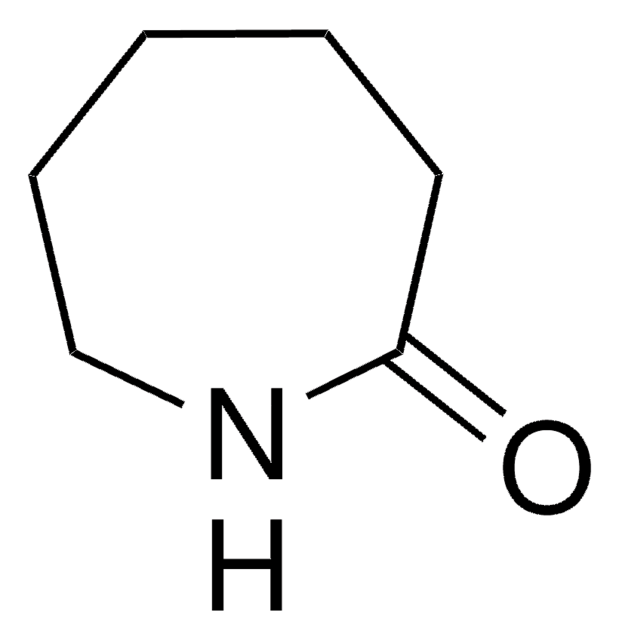

InChI

1S/C6H13NO/c1-2-3-4-5-6(7)8/h2-5H2,1H3,(H2,7,8)

InChI key

ALBYIUDWACNRRB-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

Related Categories

Application

- Silica nanoparticles–nylon 6 composites for extraction of hormones from aqueous samples.

- Polymeric nanofibers by electrospinning method. These nanofibers can be used to fabricate highly efficient nanofilters.

wgk_germany

WGK 3

flash_point_f

Not applicable

flash_point_c

Not applicable

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

In this article, we discuss issues critical to successful application of the electrospinning technique, including control of individual nanofibers to form secondary structures and assembly of nanofibers into 3D architectures.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service