464244

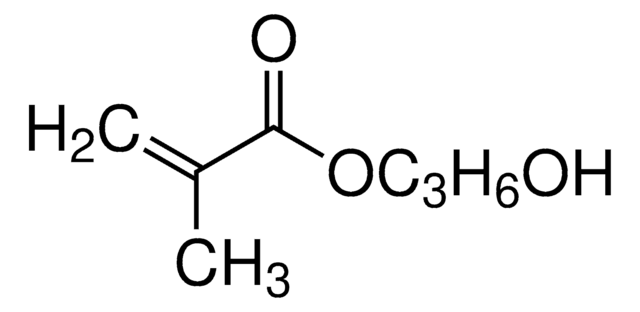

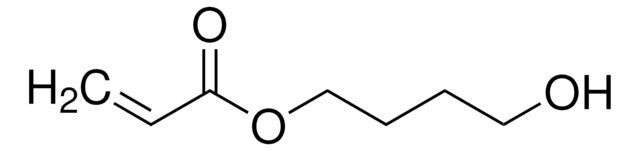

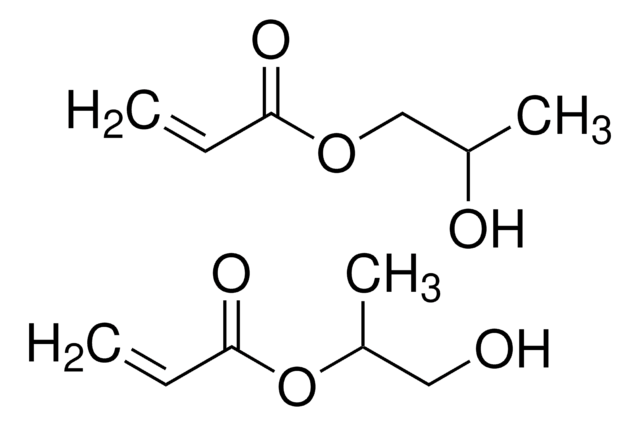

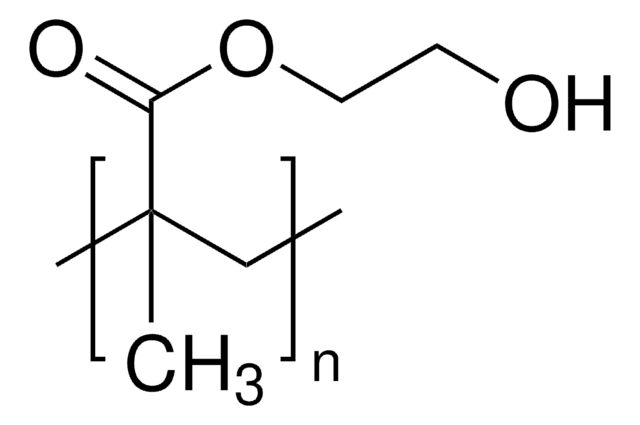

Hydroxybutyl methacrylate, mixture of isomers

94%

Synonym(s):

HOB

About This Item

Recommended Products

Quality Level

assay

94%

contains

200 ppm monomethyl ether hydroquinone as inhibitor

refractive index

n20/D 1.45 (lit.)

bp

180 °C (lit.)

density

1.006 g/mL at 25 °C (lit.)

storage temp.

2-8°C

SMILES string

O=C(OCC(O)CC)C(=C)C

InChI

1S/C8H14O3/c1-4-7(9)5-11-8(10)6(2)3/h7,9H,2,4-5H2,1,3H3

InChI key

IEVADDDOVGMCSI-UHFFFAOYSA-N

Related Categories

Application

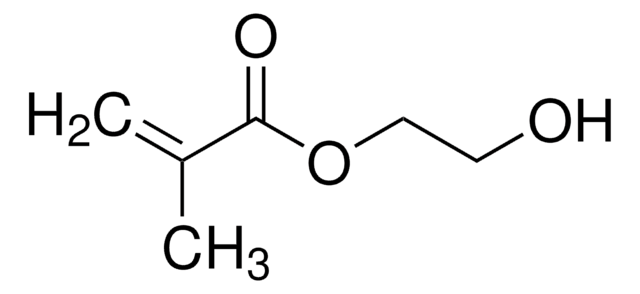

- Supplementary Information for “Permeable Protein-Loaded Polymersome Cascade Nanoreactors by Polymerization-Induced Self-Assembly”: This study involves the use of 2-hydroxypropyl methacrylate, a mixture of isomers, as a precursor in the creation of protein-loaded nanoreactors (LD Blackman et al., 2020).

- Shape-Shifting Thermoresponsive Block Copolymer Nano-Objects: Explores the use of hydroxybutyl methacrylate (HBMA) in the synthesis of block copolymer nano-objects, focusing on its ability to shift shapes in response to temperature changes (SJ Hunter et al., 2023).

signalword

Warning

hcodes

Hazard Classifications

Eye Irrit. 2 - Skin Irrit. 2 - Skin Sens. 1 - STOT SE 3

target_organs

Respiratory system

wgk_germany

WGK 3

flash_point_f

Not applicable

flash_point_c

Not applicable

ppe

Eyeshields, Faceshields, Gloves, type ABEK (EN14387) respirator filter

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

The manufacture of monomers for use in ophthalmic applications is driven by the need for higher purity, improved reliability of manufacturing supply, but ultimately by the need for the increased comfort, convenience, and safety of contact lens wearers. Daily wear contact lenses have the potential to fill this need for many customers; however, their widespread use is constrained by higher costs compared to weekly- or monthly-based lenses. New approaches that improve cost structure and result in higher quality raw materials are needed to help make contact lenses more affordable and accelerate growth of the contact lens market.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service