560596

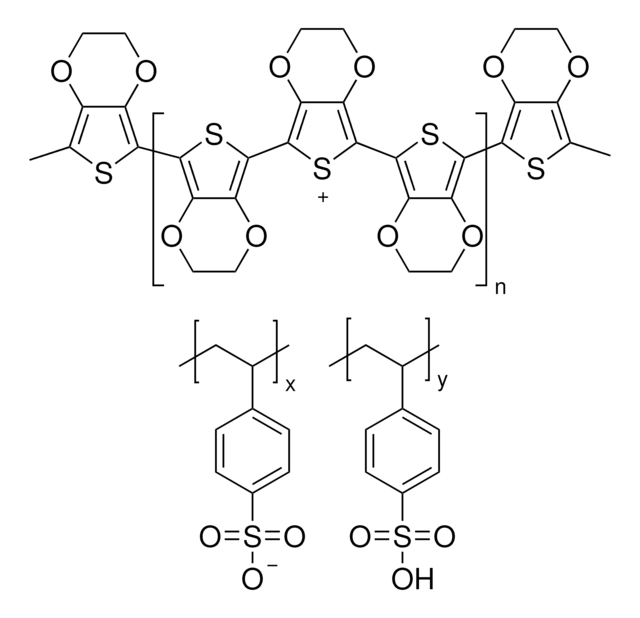

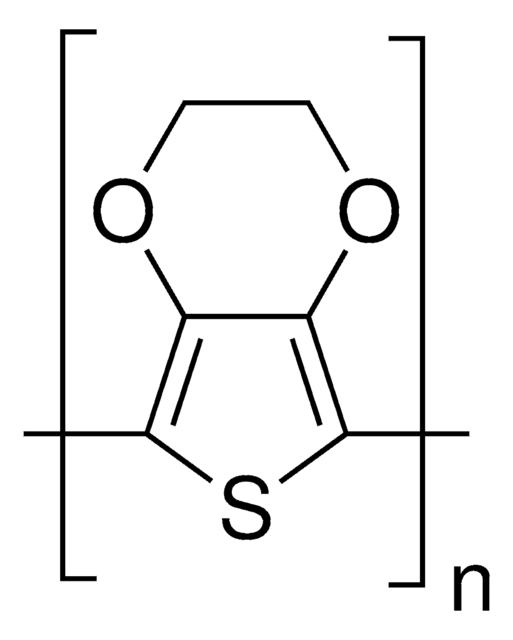

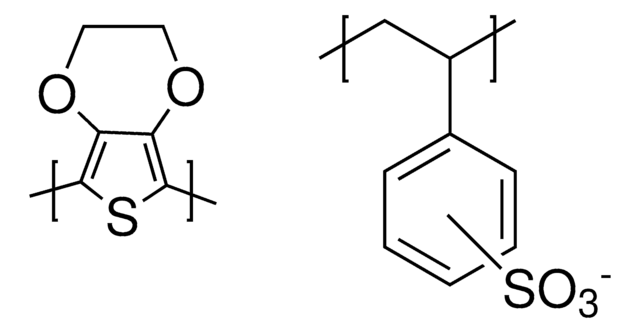

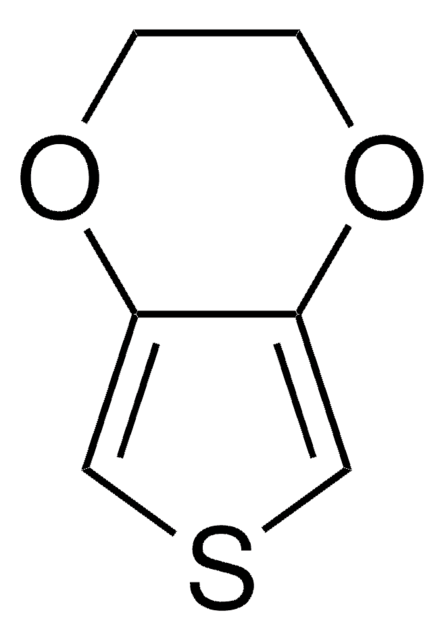

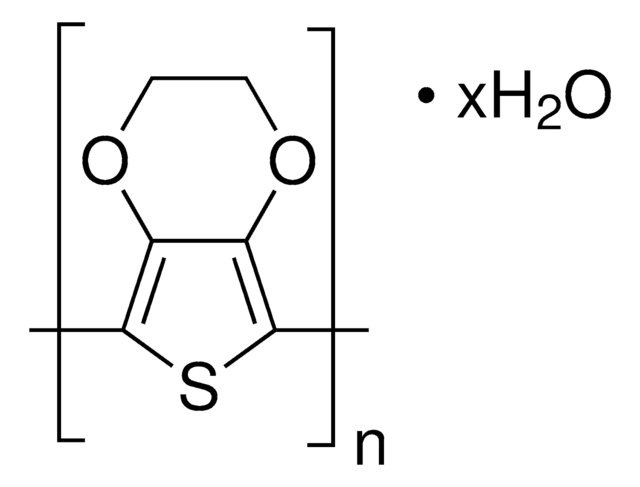

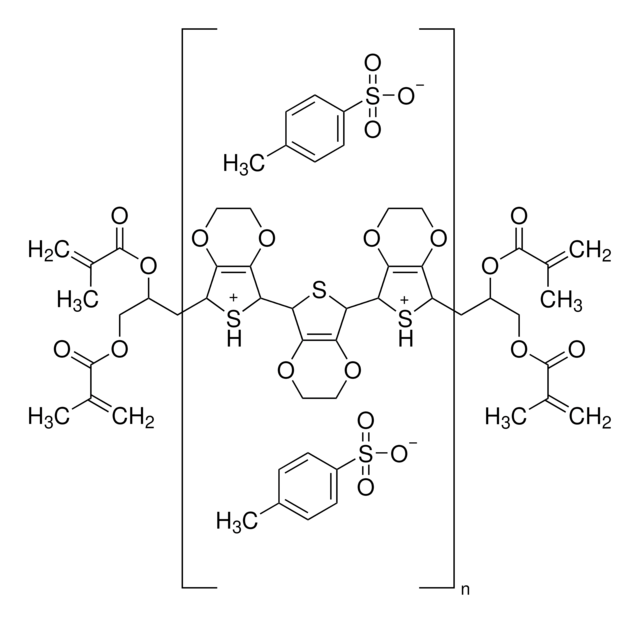

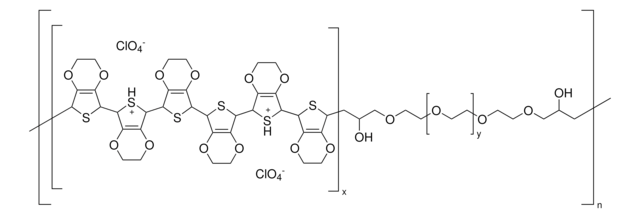

Poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate)

2.7 wt % dispersion in H2O, low-conductivity grade

Synonym(s):

PEDOT:PSS, Poly(2,3-dihydrothieno-1,4-dioxin)-poly(styrenesulfonate)

About This Item

Recommended Products

grade

low-conductivity grade

Quality Level

composition

PEDOT content, ~0.14%

PSS content, ~2.6%

concentration

2.7 wt % dispersion in H2O

impurities

<300 ppm Na

particle size

<200 nm, coeff var >95%

pH

1.2-1.8

conductivity

~1E-5 S/cm

viscosity

<20 cP(20 °C)

storage temp.

2-8°C

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

Application

Features and Benefits

Packaging

signalword

Danger

hcodes

Hazard Classifications

Eye Dam. 1 - Skin Corr. 1

Storage Class

8B - Non-combustible, corrosive hazardous materials

wgk_germany

WGK 2

flash_point_f

Not applicable

flash_point_c

Not applicable

ppe

Faceshields, Gloves, Goggles, type ABEK (EN14387) respirator filter

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Tutorial Lithography Nanopatterning at Sigma-Aldrich. Lithography, based on traditional ink-printing techniques, is a process for patterning various layers, such as conductors, semiconductors, or dielectrics, on a surface.

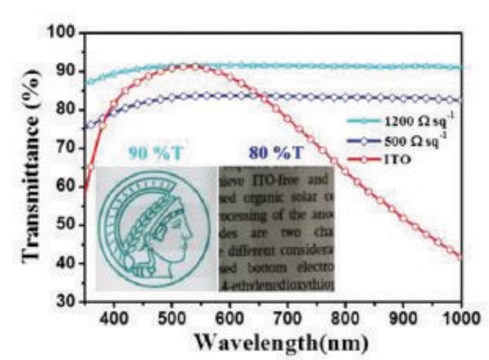

In the emerging field of organic printable electronics, such as OLEDs and organic photovoltaics (OPVs), there is a significant need for improved organic conducting and semiconducting materials. This paper reports our recent progress in two fields: 1) the development of solvent-based dispersions of the intrinsically conducting polymer (ICP) poly(3,4- ethylenedioxythiophene) (PEDOT) and 2) the synthesis of new electron-deficient (n-type) semiconducting polymers.

Conducting polymers such as polyaniline, polythiophene and polyfluorenes are now much in the spotlight for their applications in organic electronics and optoelectronics.

Find advantages of inorganic interface layer inks for organic electronic & other applications.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service