900450

Graphene dispersion

1 mg/mL in DMF, sheet resistance 4.8 kΩ/sq, avg. no. of layers, 1 ‑ 3

Synonym(s):

Conductive ink, Electrochemically exfoliated graphene ink, Graphene ink

About This Item

Recommended Products

Quality Level

form

dispersion

feature

avg. no. of layers 1 ‑ 3

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

concentration

1 mg/mL (electrochemically exfoliated graphene)

1 mg/mL in DMF

greener alternative category

, Enabling

Looking for similar products? Visit Product Comparison Guide

Related Categories

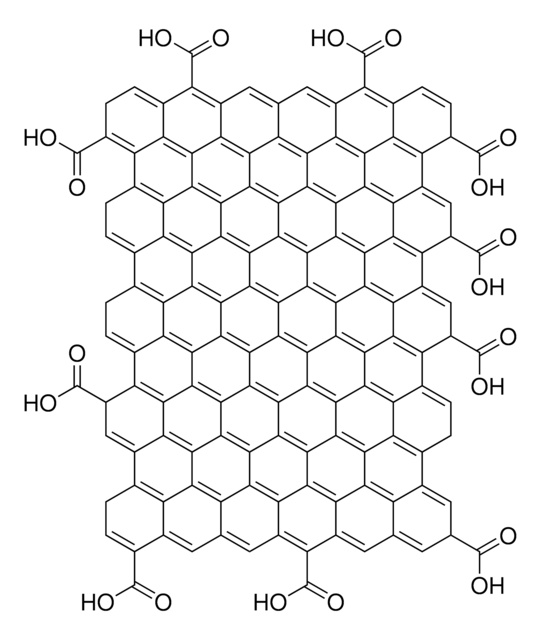

General description

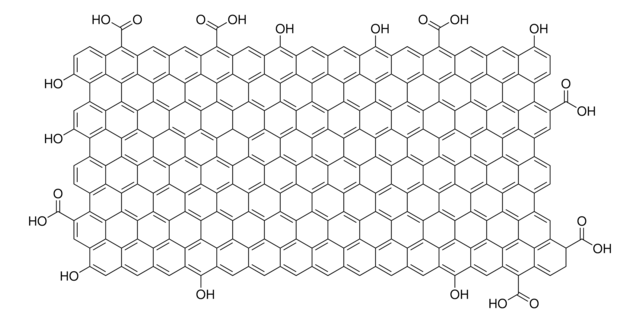

- Graphene preparation method: electrochemical exfoliation.

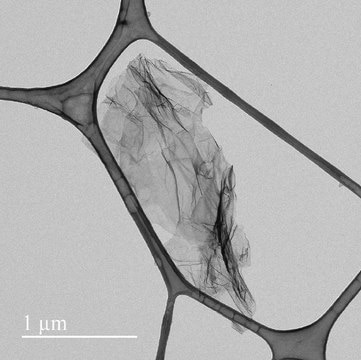

- Graphene thickness by AFM: 80%, 1-3 layers.

- Sheet size by AFM: Few micrometers

- Oxygen content: 7.5% (by XPS) (C/O-ratio: 12.3).

- Raman I_D/I_G ratio: 0.4.

- Sheet resistance: 4.8 kΩ/sq.

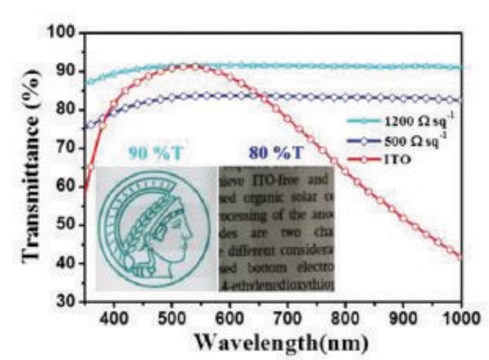

- Typical properties of films produced thereof (after dry transfer from PTFE-filter):

25 nm film: 73% transmittance, sheet resistance of 8 kΩ/sq (as made), 2.4 kΩ/sq (after 30 min, 200 °C), <1 kΩ/sq (conc. HNO3-treatment).

signalword

Danger

Hazard Classifications

Acute Tox. 4 Dermal - Acute Tox. 4 Inhalation - Eye Irrit. 2 - Flam. Liq. 3 - Repr. 1B

wgk_germany

WGK 2

flash_point_f

139.0 °F

flash_point_c

59.44 °C

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Advances in scalable synthesis and processing of two-dimensional materials

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service