916293

PhotoCol™-LAP

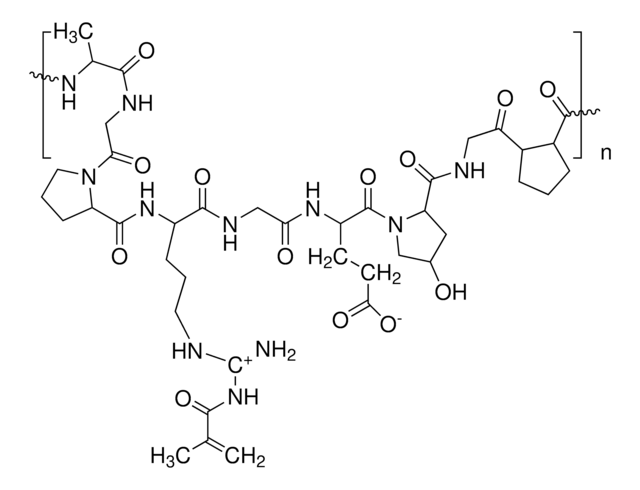

methacrylated collagen bioink kit, with LAP

Synonym(s):

3D Bioprinting, Bioink, Collagen

Sign Into View Organizational & Contract Pricing

All Photos(1)

About This Item

UNSPSC Code:

12352201

NACRES:

NA.23

Recommended Products

description

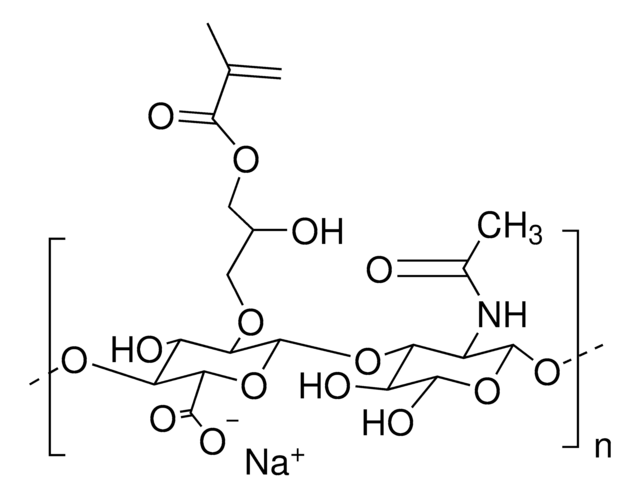

Methacrylated collagen:

Degree of methacrylation ≥ 20%

Product components :

Quality Level

sterility

sterile; sterile-filtered

form

liquid

impurities

≤10 EU/mL Endotoxin

storage temp.

2-8°C

Application

PhotoCol™-LAP bioink kit consists of purified methacrylated Type I bovine collagen as the core component with other support reagents. The methacrylated Type I collagen is produced from telo-peptide intact bovine collagen where the collagen has been modified by reacting the free amines, primarily the ε-amines groups of the lysine residues as well as the a-amines groups on the N-termini. Over 20% of the total lysine residues of the collagen molecule have been methacrylated. A bottle of 20 mM acetic acid solution is provided to solubilize the lyophilized methacrylated collagen at concentrations ranging from 3 to 8 mg/ml. The neutralization solution consists of an alkaline 10X phosphate buffered saline (PBS) solution which provides physiological salts and pH in the final mixture. The photoinitiator consists of LAP to be formulated in 1X cell culture media or PBS, which allows blue light photocrosslinking of the printed structure at 405 nm. PhotoCol™-LAP provides native-like 3D collagen gels, and the final gel stiffness can be customized by changing collagen concentrations and crosslinking.

Legal Information

PhotoCol is a trademark of Advanced BioMatrix, Inc.

wgk_germany

WGK 3

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Ian D Gaudet et al.

Biointerphases, 7(1-4), 25-25 (2012-05-17)

Type-I collagen is an attractive scaffold material for tissue engineering due to its ability to self-assemble into a fibrillar hydrogel, its innate support of tissue cells through bioactive adhesion sites, and its biodegradability. However, a lack of control of material

Erin Maloney et al.

Micromachines, 11(2) (2020-02-23)

The current drug development pipeline takes approximately fifteen years and $2.6 billion to get a new drug to market. Typically, drugs are tested on two-dimensional (2D) cell cultures and animal models to estimate their efficacy before reaching human trials. However

Andrea Mazzocchi et al.

ACS biomaterials science & engineering, 5(4), 1937-1943 (2019-11-15)

Lung cancer is the leading cause of cancer-related death worldwide yet in vitro disease models have been limited to traditional 2D culture utilizing cancer cell lines. In contrast, recently developed 3D models (organoids) have been adopted by researchers to improve

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service