925217

TissueFab® - low endotoxin GelMA-UV bioink

0.2 μm filtered, suitable for 3D bioprinting applications

Synonym(s):

Bioink, GelMA, Gelatin methacrylamide, Gelatin methacrylate, Gelatin methacryloyl

Sign Into View Organizational & Contract Pricing

All Photos(1)

About This Item

UNSPSC Code:

12352201

NACRES:

NA.23

Recommended Products

Quality Level

sterility

0.2 μm filtered

form

viscous liquid (to gel)

size

10 mL

impurities

≤5 CFU/g Bioburden

≤5 CFU/g Bioburden (Aerobic)

≤50 EU/mL Endotoxin

color

pale yellow to colorless

pH

6.5-7.5

viscosity

2-20 cP

application(s)

3D bioprinting

storage temp.

2-8°C

Related Categories

General description

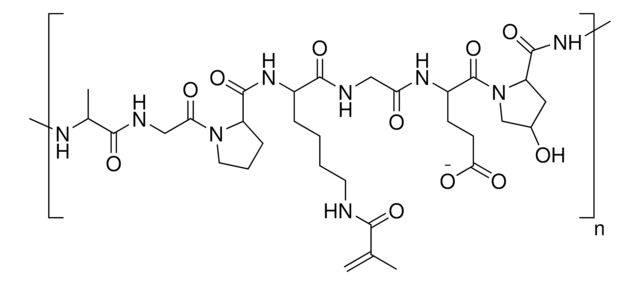

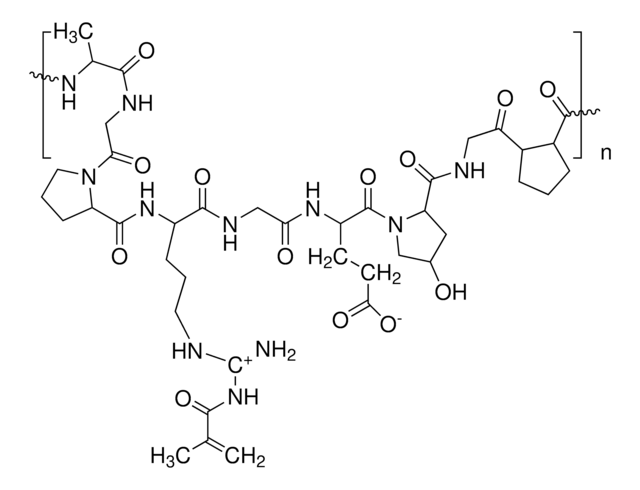

Gelatin methacryloyl (GelMA) is a polymerizable hydrogel material derived from natural extracellular matrix (ECM) components. Due to its low cost, abundance, and retention of natural cell binding motifs, gelatin has become a highly sought material for tissue engineering applications.

The addition of photocrosslinkable methacrylamide functional groups in GelMA allows the synthesis of biocompatible, biodegradable, and non-immunogenic hydrogels that are stable in biologically relevant conditions and promote cell adhesion, spreading, and proliferation.

Temporal and spatial control of the crosslinking reaction can be obtained by adjusting the degree of functionalization and polymerization conditions, allowing for the fabrication of hydrogels with unique patterns, 3D structures, and morphologies.

The addition of photocrosslinkable methacrylamide functional groups in GelMA allows the synthesis of biocompatible, biodegradable, and non-immunogenic hydrogels that are stable in biologically relevant conditions and promote cell adhesion, spreading, and proliferation.

Temporal and spatial control of the crosslinking reaction can be obtained by adjusting the degree of functionalization and polymerization conditions, allowing for the fabrication of hydrogels with unique patterns, 3D structures, and morphologies.

Application

Gelatin methacrylate based bioinks have been used in the following bioprinting applications:

- osteogenic,

- chondrogenic ,

- hepatic ,

- adipogenic ,

- vasculogenic ,

- epithelial ,

- endothelial ,

- cardiac valve ,

- skin ,

- tumors

Features and Benefits

- Ready-to-use formulation optimized for high printing fidelity and cell viability, eliminating the lengthy bioink formulation development process

- Step-by-step protocols developed and tested by MilliporeSigma 3D Bioprinting Scientists, no prior 3D bioprinting experience neede

- Suitable for different extrusion-based 3D bioprinter model

- Methacrylamide functional group can also be used to control the hydrogel physical parameters such as pore size, degradation rate, and swell ratio.

Legal Information

TISSUEFAB is a registered trademark of Merck KGaA, Darmstadt, Germany

wgk_germany

WGK 3

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Y Shi et al.

Biomedical materials (Bristol, England), 13(3), 035008-035008 (2018-01-09)

Three-dimensional bioprinting is an emerging technology for fabricating living 3D constructs, and it has shown great promise in tissue engineering. Bioinks are scaffold materials mixed with cells used by 3D bioprinting to form a required cell-laden structure. In this paper

Wanjun Liu et al.

Advanced healthcare materials, 6(12) (2017-05-04)

Bioprinting is an emerging technique for the fabrication of 3D cell-laden constructs. However, the progress for generating a 3D complex physiological microenvironment has been hampered by a lack of advanced cell-responsive bioinks that enable bioprinting with high structural fidelity, particularly

B Duan et al.

Acta biomaterialia, 10(5), 1836-1846 (2013-12-18)

Tissue engineering has great potential to provide a functional de novo living valve replacement, capable of integration with host tissue and growth. Among various valve conduit fabrication techniques, three-dimensional (3-D) bioprinting enables deposition of cells and hydrogels into 3-D constructs

Methacrylated gelatin and mature adipocytes are promising components for adipose tissue engineering.

Birgit Huber et al.

Journal of biomaterials applications, 30(6), 699-710 (2015-05-29)

In vitro engineering of autologous fatty tissue constructs is still a major challenge for the treatment of congenital deformities, tumor resections or high-graded burns. In this study, we evaluated the suitability of photo-crosslinkable methacrylated gelatin (GM) and mature adipocytes as components

Wanjun Liu et al.

Biofabrication, 10(2), 024102-024102 (2017-11-28)

Bioinks with shear-thinning/rapid solidification properties and strong mechanics are usually needed for the bioprinting of three-dimensional (3D) cell-laden constructs. As such, it remains challenging to generate soft constructs from bioinks at low concentrations that are favorable for cellular activities. Herein

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service