Recommended Products

material

natural rubber septa

color

red

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

Mixed set includes:

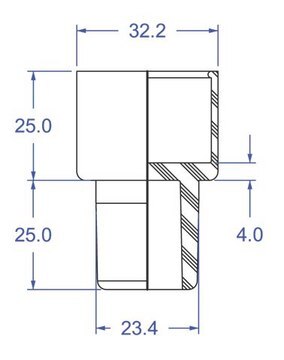

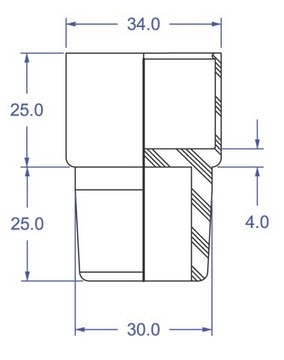

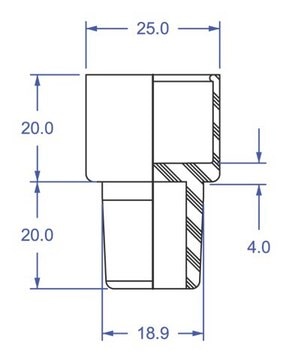

25 ea of the 7 mm O.D., and 8 mm O.D.

20 ea of the 10 mm O.D., 13 mm I.D., and 10/30 joint

10 ea of the 14/20 joint, 19/22 joint, 24/40 joint

5 ea of the 29/42 joint

25 ea of the 7 mm O.D., and 8 mm O.D.

20 ea of the 10 mm O.D., 13 mm I.D., and 10/30 joint

10 ea of the 14/20 joint, 19/22 joint, 24/40 joint

5 ea of the 29/42 joint

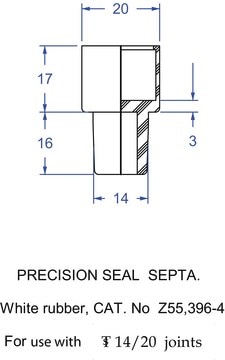

The recommended choice for use with organic chemicals and solvents, pressure applications, and cannulation techniques:

Precision Seal septa are designed specifically for the rigorous requirements of chemical applications.

Typical specification results:

Compression recovery - Excellent

Self-sealing - Excellent

Strength - Excellent

Puncture Target Area - 40% greater than standard septa

Upper Heat limit - 85°C

Extractables (Hexanes) - 1.9%

Volatile Matter - 0.19%

Ash Content - 0.24%

Rubber composition:

Standard rubber no. 1, accelerator, oxidizer, hard resin acid, anti-ager, lime carbonate, dye agent.

Storage Note for Natural Rubber Septa: Store septa in a closed bag out of sunlight to retard blooming, which is the formation of a whitish film on the surface of the rubber. Blooming is a natural process and does not affect performance. Remove visible bloom by washing or wiping off before use.

SAFETY ADVICE: The Precision Seal flexible sleeve must be secured to the glass joint with a Wrap-It Tie or similar device during cannulation and for applications that involve pressure. DO NOT rely on the sleeve alone to anchor the septum. This rule applies to all types of rubber septa that are used for critical applications.

Precision Seal septa are designed specifically for the rigorous requirements of chemical applications.

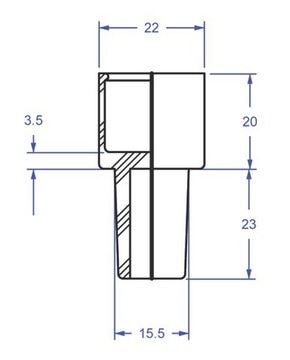

- Precision fit: Precision Seal septa have a longer, tapered plug that seats firmly inside the glass joint or tube providing a sealing surface that is 50 to 80% greater than standard sleeve stoppers. The inner seal design of Precision Seal septa minimizes chemical and solvent vapor migration up the joint to the sleeve which can swell, leak, or fail from exposure. The surface texture of the rubber is similar to that of a ground glass joint and resists movement once seated.

- Non-contaminating: Precision Seal natural rubber is lower in solvent extractables: 1.9% vs. standard sleeve stoppers: 5-6%. Precision Seal rubber is higher in density to minimize the effects of solvent degradation. They are manufactured from a single, certified lot for absolute consistency.

- Safety and Performance: Septa must not slide through the joint or pop-off during cannulation or when under pressure. Pushing on the Precision Seal septum actually tightens the tapered plug to prevent movement. The flexible sleeve on septa sizes for glassware joints is heavy wall and oversized to make folding over glass joints safer. The seal is made by the tapered plug within the joint and not the flexible sleeve.

Typical specification results:

Compression recovery - Excellent

Self-sealing - Excellent

Strength - Excellent

Puncture Target Area - 40% greater than standard septa

Upper Heat limit - 85°C

Extractables (Hexanes) - 1.9%

Volatile Matter - 0.19%

Ash Content - 0.24%

Rubber composition:

Standard rubber no. 1, accelerator, oxidizer, hard resin acid, anti-ager, lime carbonate, dye agent.

Storage Note for Natural Rubber Septa: Store septa in a closed bag out of sunlight to retard blooming, which is the formation of a whitish film on the surface of the rubber. Blooming is a natural process and does not affect performance. Remove visible bloom by washing or wiping off before use.

SAFETY ADVICE: The Precision Seal flexible sleeve must be secured to the glass joint with a Wrap-It Tie or similar device during cannulation and for applications that involve pressure. DO NOT rely on the sleeve alone to anchor the septum. This rule applies to all types of rubber septa that are used for critical applications.

Legal Information

Precision Seal is a registered trademark of Merck KGaA, Darmstadt, Germany

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service