Z683477

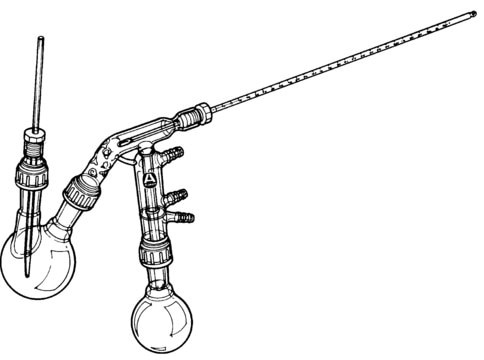

Aldrich® Kugelrohr™ short-path distillation apparatus

AC/DC input 115 V AC

Synonym(s):

apparatus for distillation, ball tube distillation, distillation apparatus, distilling apparatus, fractional distillation apparatus, glass distillation apparatus, kugelrohr apparatus, kugelrohr distillation, short path distillation apparatus, vacuum distillation apparatus

About This Item

Recommended Products

parameter

220 °C temp. limit

W × H × D

25 in. × 18 in. × 11 in.

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

High Vacuum Capability and Safe Front Loading Design

Distillation Applications:

- Heat-sensitive compounds

- Liquids and low-melting solids from polymers and tars

- Removes color and particulates

- Suitable for sublimation and solvent evaporation

Features:

- Air bath oven distills up to 230°C

- 25 mL to 2 L flask capacity

- Front Loading oven door with safety glass viewing window

- Interchangeable PTFE support bearings for flask joint 14/20

- Digital, thermocouple temperature control

- Front panel with controls for temperature, vacuum and motor drive

- Adjustable receiving flask cooling bath

- Oscillating drive motor

Specifications:

- Oven flask size range: 25 mL to 2 L

- Heating range: ambient to 230°C, +/- 3°C across span after stabilization

- Power: 120/240 VAC +/- 10%, 50/60 Hz +/- 3%, detachable power cord

- Fuses: Heater 7.5 A, Vac 2.5 A, Power input 10 A

- Heater: 900 W

- Size: 25 in. W x 11 in. D x 18 in. H, (30 in. clearance required with door open)

- Rotation: 270 deg each direction

- Operating environment: 32 to 40°C, 0 to 90% RH, noncondensing

- CE, WEEE and RoHS complilant

Ordering Note: Purchase Kugelrohr glassware separately.

Note: A trap between the receiving flask/s and vacuum pump is recommended.

Applications related to marijuana extraction/production are not supported.

Typical operation:

Step 1. Fill the load (oven) flask (25 mL to 2 L) one-third full with distillable material. Connect the load flask to the motor drive coupling inside the oven. Connect the load flask to a horizontal receiving flask outside the oven. Connect a straight tube to the receiving flask and to a vacuum source with rubber tubing.

Step 2. A vacuum pump may be plugged into the receptacle on the rear of the oven and switched on and off from the Kugelrohr front control panel.

Step 3. Fill cooling tray with ice.

Step 4. Turn on the Kugelrohr main power switch. Set the distillation temperature on the front control panel, turn on the motor drive and vacuum pump.

Step 5. Collect distillate in the horizontal receiving flask outside the oven.

Legal Information

accessory

related product

replacement part

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service